Short lead times – as usual

Fast – flexible – precise

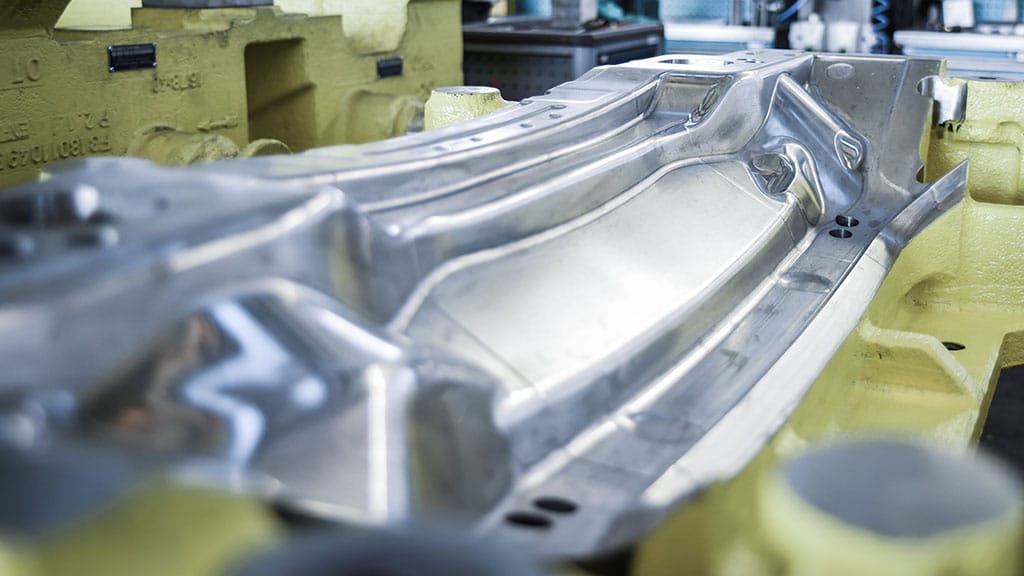

As a recognised partner of the automotive industry, the WBL Group manufactures large-scale tools for structural and body shell parts in the shortest possible time.

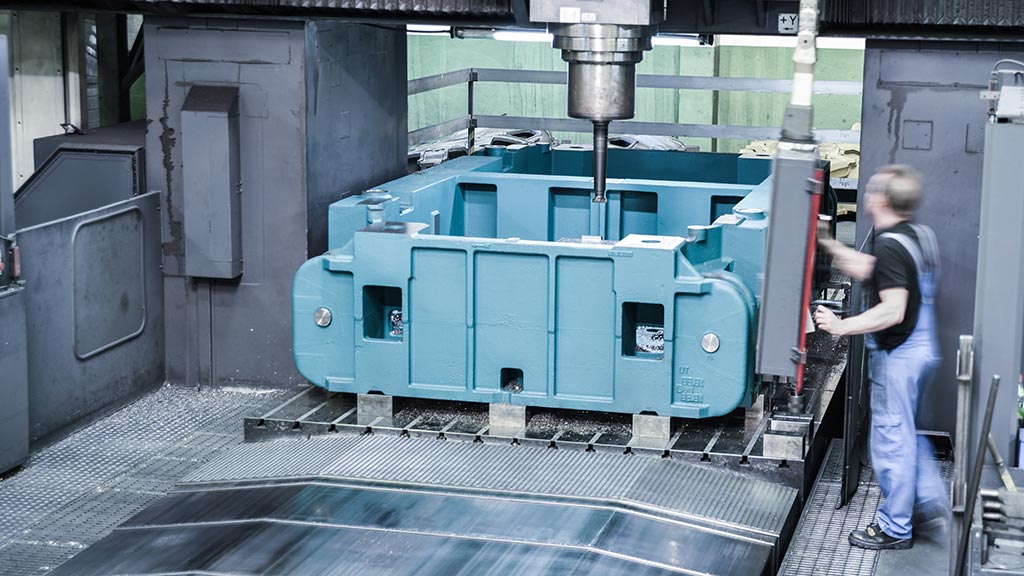

With 50 t cranes, tryout presses with a press force of up to 25,000 kN and state-of-the-art mechanical production, our assembly halls create the conditions for an optimum infrastructure.

Four assembly teams at each location oversee production of the respective tools throughout the entire tool manufacturing process, right through to training for our customers.

This mix of a modern infrastructure and skilled craftsmanship guarantees process-reliable series production!

Standardised tool development process

A standardised tool development process ensures delivery 100% on schedule and the shortest possible lead times.

- Inquiry for a new tool

As part of your inquiry, we clarify the technical specifications and required scheduling milestones. - Preparation of an offer

We create an individual, non-binding offer for the customer on the basis of the inquiry. - Receipt of order and reservation of capacities

In the case of an incoming order, all commercial, technical and capacitive details have already been clarified. - Kickoff

A kickoff meeting is held with all involved project members immediately after receipt of order. The project team takes charge of the toolmaking process.

- The project manager draws up a detailed milestone plan for the transparent depiction of the project schedule.

The project manager is the technical contact for our customers during the entire toolmaking process.

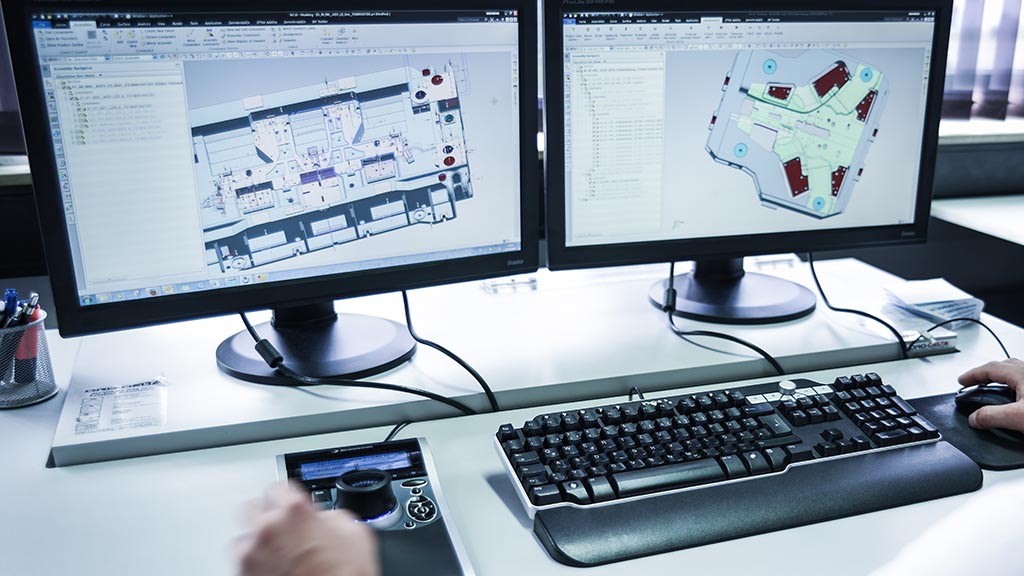

- Tool design

Definition of the ultimate method and determination of material thinning and springback with AutoForm©. - Detailed design

State-of-the-art design: CATIA V5 + Siemens NX.

- Procurement process

Capacities for model and casting machining are secured at the earliest possible time. - Work preparation

Milling data and NC programs are created. - Mechanical production

A combination of system-supported milling planning and the latest machinery ensures punctual delivery to the assembly team. - Tool assembly

Individual tool elements are completed in the shortest possible time in four assembly teams and prepared for tryout. - Tryout

Tryout presses with a press force of up to 25,000 kN are used to prepare the tools for final acceptance and produce the first off-tool parts. - Sampling

Tactile and optical measurement systems are employed to create test and measurement protocols. - Final acceptance by the customer

Our assembly teams break in the tools on series production presses at customers’ premises.

Passion and experience for process-reliable production

We guarantee our customers process-reliable series production based on many years of experience, skilled craftsmanship and use of the latest technology.